The Engineering of Spontaneity: How Soloscopic Tech Fixes the "Travel Rod" Compromise

Update on Nov. 18, 2025, 6:15 p.m.

In the world of angling, there is a concept I like to call “Gear Friction.” It’s the mental calculation you make before a trip: Is it worth hauling the 7-foot one-piece rod? Will it fit in the car? Will it get snapped in the trunk? Too often, the answer is no, and the opportunity to fish is lost.

For years, the solution was the telescopic rod. Historically, however, these were synonymous with compromise—stiff, insensitive “toys” that felt more like collapsing antennas than precision instruments. They suffered from what engineers call “dead spots” in the blank’s curvature.

But materials science has evolved. The modern era of mobile angling isn’t about making do with inferior gear; it’s about leveraging technology to maintain performance while shrinking the footprint. Leading this charge is a design philosophy known as Soloscopic Performance Technology, a hybrid approach exemplified by the KastKing Blackhawk II.

Let’s deconstruct the physics behind why traditional travel rods failed, and how modern engineering is fixing the “dead spot” problem.

The Physics of the “Dead Spot” (and How to Kill It)

The primary flaw in early telescopic rods was the joint system. In a standard multi-piece rod, wherever two sections overlap (the ferrule), the rod becomes effectively double-walled and rigid. If you have six sections, you have five rigid points that refuse to bend.

When you hook a fish, the rod should form a parabolic arc to distribute tension. Rigid joints interrupt this arc, creating flat areas or “dead spots.” These spots are where stress concentrates, leading to snapped lines or, worse, shattered graphite.

The Solution: The Floating Guide System

This is where the engineering in the Blackhawk II becomes interesting. Instead of fixing guides solely to the end of each section, it utilizes Floating Guides.

These guides are mounted on sliding sleeves that sit between the fixed ends of the telescopic sections. * Arc Management: By positioning guides on the “floating” areas of the blank, the line tension forces the rod to flex in the gaps between the joints. * Stress Distribution: The floating guides act as fulcrums, bridging the dead spots and allowing a 6-piece rod to mimic the smooth power transition of a 2-piece rod.

This system is the cornerstone of Soloscopic Performance Technology. It converts a segmented tube into a cohesive, tension-bearing instrument.

Material Hybridization: The “Modulus” Trade-Off

Another critical aspect of travel rod engineering is the blank material. You will often see terms like “24-Ton Carbon” or “IM6 Graphite.” This refers to the tensile modulus—essentially, the stiffness of the fibers.

- High Modulus (High Ton): Extremely sensitive and light, but brittle. It transmits vibration instantly (great for feeling bites) but shatters easily under impact.

- Low Modulus (Glass): Heavy and flexible, but incredibly durable.

A travel rod lives a hard life. It gets tossed in backpacks, strapped to bikes, and banged against rocks. A pure high-modulus carbon rod wouldn’t survive a week of real-world travel.

The Blackhawk II addresses this via Material Hybridization. The main body uses a Toray 24-Ton Carbon Matrix, which offers a “sweet spot” balance—light enough for fatigue-free casting, but tough enough to handle the knocks of travel.

However, the tip—the most fragile part of any rod—is where the real innovation lies. KastKing integrates a Solid Glass Tip. Unlike hollow carbon tips which can crush or snap if high-sticked, solid fiberglass is nearly indestructible in normal use. It adds a degree of “visual sensitivity” (you see the bend before you feel it) and protects the rod from the most common failure point in travel gear.

The “Go-Bag” Protocol: Engineering Spontaneity

The true value of this technology isn’t just in the catch; it’s in the access. By reducing the friction of transport, you increase your “Time on Water” (TOW).

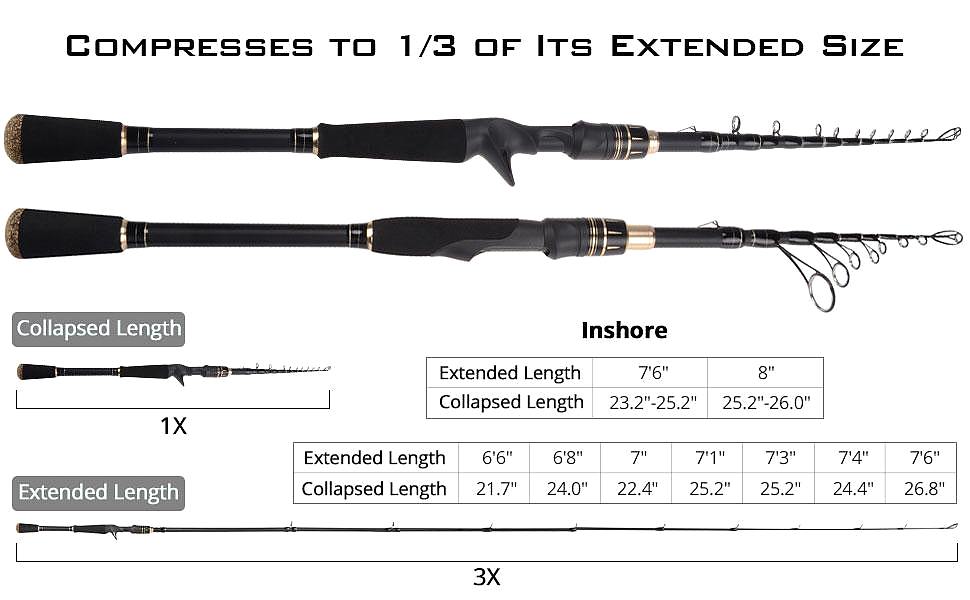

Consider the Urban Angler’s Loadout: * The Rod: Collapses to roughly 21 inches (depending on the model). * The Reel: A 2000-3000 series spinning reel can remain attached. * The Rig: Because of the floating guides, you can leave the line strung through the eyelets with a snap swivel attached.

Deployment Speed:

With a traditional 4-piece travel rod, you are threading line through eyelets every time. With a pre-rigged Soloscopic system, deployment takes approximately 45 seconds:

1. Unzip the case.

2. Extend from the tip down (crucial for locking the floating guides).

3. Align the guides visually.

4. Cast.

This capability transforms a 20-minute lunch break or a roadside stop into a viable fishing session.

Field Notes: Operational Realities and Maintenance

While the engineering is sound, potential users must understand the operational realities of Soloscopic rods to get the best performance. These are not “set and forget” tools like their one-piece cousins.

1. The Alignment Tax

Unlike 2-piece rods that often feature alignment dots, most telescopic rods, including the Blackhawk II, require manual alignment.

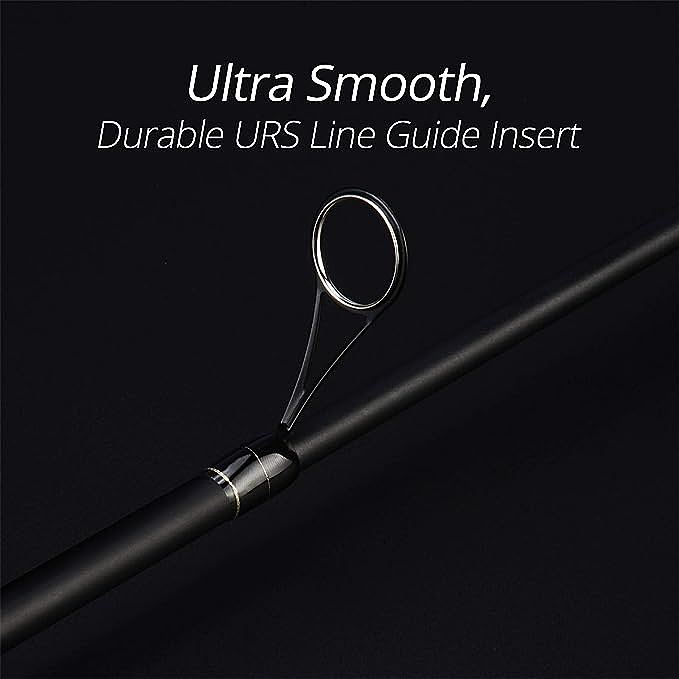

* Pro Tip: Sight down the spine of the rod (the side opposite the guides for spinning rods) to ensure a straight path. Misaligned floating guides will increase friction and reduce casting distance.

2. The “Sandpaper” Effect

Telescopic joints rely on friction fits. If sand or grit gets into a joint, it acts like sandpaper, wearing down the carbon every time you extend or collapse it.

* Protocol: If you fish in sandy or saltwater environments, wipe down each section with a damp cloth before collapsing the rod. Never force a gritty section closed.

3. The “Stick” Fix

A common issue with friction ferrules is getting them stuck (usually from pulling too hard when cold, then the rod heating up).

* Correction: Never use pliers. Grip the rod behind the knees and use the torque of your legs to twist, or use a rubber jar opener for grip. Twist and push simultaneously; never just push.

Conclusion: The End of the “Backup” Rod

For a long time, the telescopic rod was the “backup”—the rod you used only when you couldn’t use a “real” rod. Soloscopic Performance Technology challenges that hierarchy.

By solving the dead spot issue through floating guides and addressing durability through hybrid materials, the KastKing Blackhawk II represents a shift in category. It is no longer just a tool of convenience; it is a viable primary instrument for the mobile angler. It allows us to reclaim the water that lies between our departure and our destination, proving that the best fishing rod is simply the one you have with you.