The Soul of the Rod: From Bamboo to Carbon Fiber, The Science in Your Hands

Update on Aug. 1, 2025, 3:56 p.m.

There is a moment in angling that transcends the mere act of catching a fish. It’s a quiet, electric dialogue. It begins with a subtle curiosity hundreds of feet away, a bump or a pull from a world unseen. This faint whisper travels up a filament of line, and then, it strikes the rod. What happens next is a small miracle of physics and material science. The rod doesn’t just bend; it translates that whisper into a language your hands can understand. It becomes an extension of your nervous system.

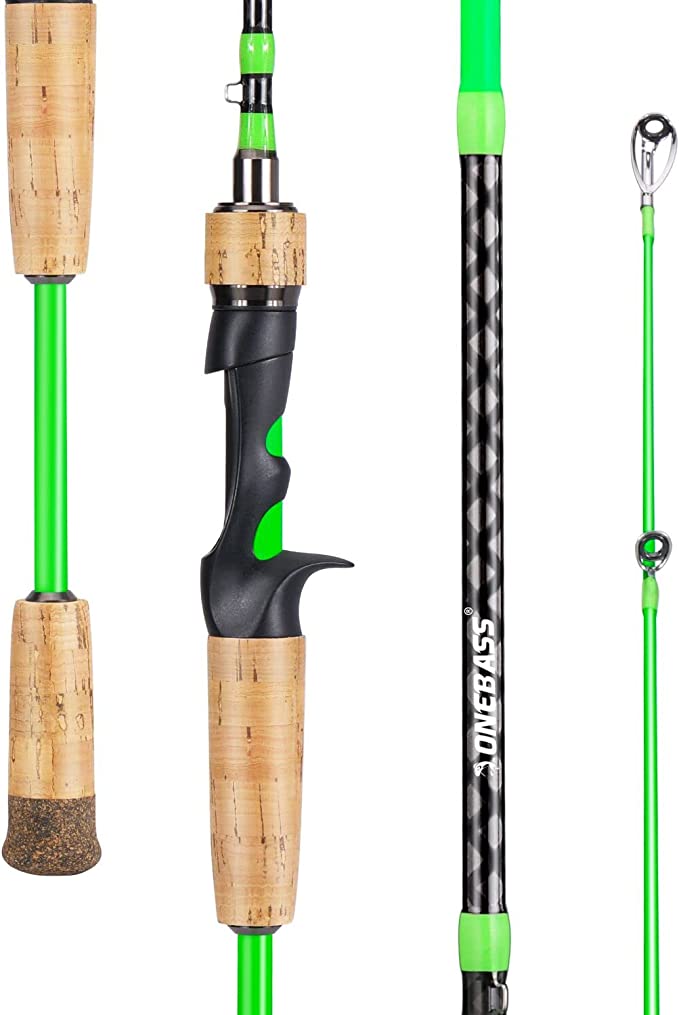

This conversation is mediated by the tool in your hands. A modern fishing rod, like the popular QudraKast R-210G-1, is far more than a simple lever. It is a finely tuned instrument, the culmination of a century-long quest for the perfect balance of lightness, strength, and sensitivity. To hold one is to hold a piece of history, a story of how humanity learned to shape materials, from humble wood to aerospace composites, all in pursuit of a clearer conversation with the life beneath the water.

The Age of Whispers: Wood, Cane, and the Quest for Feel

For centuries, the angler’s rod was a product of nature. A straight sapling of hickory, a carefully selected stalk of bamboo—these were the first instruments. The goal was simple: a pole long enough to place a bait and strong enough to haul a fish ashore. But even then, artisans knew that not all woods were created equal. The true art lay in finding a material that offered a lively, resilient flex.

The pinnacle of this natural-material era was the split cane rod. Master craftsmen would split Tonkin bamboo into precise, triangular strips and glue them together, typically in a hexagonal cross-section. This was a process of turning a natural, imperfect material into a tool of remarkable consistency and feel. A well-made split cane rod had a soulful, progressive flex, storing the energy of a backcast and releasing it with a graceful authority. It was, however, heavy, fragile, and astronomically expensive. It was a beautiful whisper, but one few could afford to hear. The fundamental challenge remained: how to create that strength and feel reliably, affordably, and durably.

The Roar of Revolution: Fiberglass and the Democratization of Angling

The answer came not from a riverbank, but from the industrial crucible of World War II. Fiberglass, a material of woven glass strands bonded with resin, was developed for military applications. After the war, this technology flowed into the civilian market, and for fishing, it changed everything.

Fiberglass rods were a revolution. They were virtually indestructible compared to cane, impervious to weather, and, most importantly, they could be mass-produced. Suddenly, a high-performing fishing rod was within reach of the average person. Angling was democratized. These rods, however, spoke a different language. Fiberglass is defined by its superb flexibility and toughness, but it has a lower stiffness-to-weight ratio than cane. In scientific terms, it has a lower Young’s Modulus. This means it bends more easily but also dampens vibrations more. The whisper from the fish became a duller thud. The conversation was clearer in its strength, but lost some of its nuance. For millions of new anglers, it was a trade-off they were happy to make.

The Sharp Crack of a New Era: The Carbon Fiber Ascent

The next great leap came, once again, from the aerospace industry. In the quest for lighter and stronger aircraft components, engineers perfected carbon fiber. This material is made of carbon atoms bonded together in crystals that are aligned into long, thin filaments. When woven into a fabric and set in resin, it creates a material of almost otherworldly properties. Its stiffness-to-weight ratio is extraordinary.

When this technology was applied to fishing rods, it was transformative. A carbon fiber rod is incredibly light and incredibly stiff. This high stiffness, or high modulus, means it resists bending and, crucially, transmits vibrations with breathtaking efficiency. The energy from a fish’s bite travels up the blank at high speed with minimal vibration damping. The dull thud of fiberglass was replaced by a sharp, crisp crackle of information. Anglers could now feel not just the bite, but the lure ticking along the bottom, the subtle change from sand to gravel, the whisper before the strike. This is the “sensitivity” that defines the modern fishing rod, and it’s a direct result of the material science born in the stars.

The Harmony of the Composite: A Deliberate Duet

This brings us to the rod in question. The QudraKast R-210G-1 lists its materials as a blend of Carbon Fiber, Graphite (a form of carbon fiber), and Fiberglass. This is not a step backward. It is a deliberate and intelligent engineering choice—the creation of a composite. Pure, high-modulus carbon fiber is sensitive but can be brittle. A sharp impact against a rock could lead to catastrophic failure.

By weaving fiberglass back into the carbon fiber matrix, designers create a material that plays a duet. The carbon fiber provides the rigid, lightweight backbone, forming the primary pathway for those crisp vibrations. The fiberglass acts as a shock absorber, adding immense durability and impact resistance. It ensures that when the rod is bent into a deep arc under the strain of a powerful fish, it complies with Hooke’s Law—flexing and storing energy without fracturing. The result is a rod that is both sensitive enough to feel the whisper and tough enough to withstand the roar. It is the perfect, versatile language for the varied species—from crafty trout to brawling catfish—that the everyday angler pursues.

Strength in Form: The Hidden Genius of the X-Wrap

Look closely at the surface of many modern rods, including this one with its “X-Warping Painting.” This crisscross pattern is far more than a cosmetic flourish. It is the visual evidence of a fundamental engineering principle applied to solve an age-old problem. A fishing rod is a hollow tube, and when you bend a hollow tube, its cross-section wants to deform, to flatten into an oval. This process, called ovalization, dramatically weakens the structure.

The external X-wrap of fibers creates a reinforcing cage around the blank. It provides what engineers call Hoop Strength. These helical windings directly counter the forces that would crush the tube, ensuring the blank maintains its circular profile and structural integrity even under maximum load. It’s a beautifully efficient way to add immense strength with minimal weight, allowing the core carbon fibers to do their job of transmitting the bite.

Conclusion: The History in Your Hand

When all these elements come together—the composite blank, the reinforcing wrap, and a modern telescopic design that allows a 7-foot rod to travel in a backpack—the result is remarkable. The QudraKast R-210G-1 is a testament to how far we have come. It embodies the sensitivity of carbon fiber, the toughness of fiberglass, and the engineering that makes it both strong and portable.

The next time you stand by the water, take a moment to consider the tool in your hand. It is a direct descendant of a bamboo stalk, refined by the science of flight and the pragmatism of engineering. Understanding the soul of your rod—the story of its materials and the genius of its design—doesn’t just make you a more informed angler. It deepens the connection, sharpens your perception, and transforms that electric moment of the bite into a conversation with a rich and vibrant history.