Precision Spooling Science: Elevating Your Cast with Advanced Line Management

Update on Nov. 19, 2025, 2:24 p.m.

In the intricate physics of angling, the connection between angler and fish hangs literally by a thread. Yet, for a component so critical, fishing line is often treated with surprising negligence until the moment it fails. The difference between a personal best landed and a heartbreaking “ping” often comes down to the integrity of the line sitting on your spool. While modern metallurgy has given us featherlight reels and aerospace-grade rods, the method of applying line to those reels has, for many, remained stuck in the dark ages of pencils, toes, and phone books.

True line management is not merely a chore of replenishment; it is a foundational discipline of the sport. It involves understanding tension, eliminating torsional stress (twist), and managing the lifecycle of expensive braids and fluorocarbons. The evolution of specialized tools, exemplified by devices like the Piscifun TL029 Speed X Fishing Line Spooler, signals a shift from makeshift solutions to precision engineering. Let’s deconstruct why upgrading your spooling process is one of the most impactful technical adjustments you can make.

The Physics of the “Wind Knot”: Why Tension Matters

The scourge of the “wind knot” is rarely the fault of the wind. More often, it is a symptom of poor line lay, specifically caused by inconsistent tension during the spooling process. When line—especially braided superline—is wound loosely or unevenly, subsequent casts can cause outer layers to dig into the softer inner layers. Under the high torque of a hookset or a heavy cast, this buried line creates friction, resulting in snaps or catastrophic tangles.

Achieving what engineers call “concentric density” on a spool requires a steady, adjustable drag force during application. This is where the human hand fails and mechanical advantage succeeds. The architecture of the Speed X creates a controlled environment for this tension. By utilizing a noise-reduction conical adapter, the device centers the bulk spool perfectly. Unlike loose-fitting rods that allow the spool to wobble and dispense line in jerky spurts, the conical design ensures a smooth, rotational feed. This synchronization between the bulk spool and the reel means every inch of line is laid down under constant, uniform pressure, creating a rock-solid base for your fishing.

Decoupling the Twist: Spinning vs. Casting Dynamics

Line twist is the enemy of presentation. It causes lures to spin unnaturally and reduces casting distance by increasing friction through the guides. The mechanics of twist generation differ significantly between reel types, and a competent spooling station must accommodate both.

- Baitcasters: These winches require line to come off the top of the bulk spool directly onto the reel spool. The Speed X’s stable clamping system creates a linear feed path ideal for this direct transfer.

- Spinning Reels: Here lies the complexity. Because the bail arm wraps line around a stationary spool, twisting is inherent if the feed isn’t managed correctly. The ability to adjust the orientation and tension on the Speed X allows anglers to mitigate this.

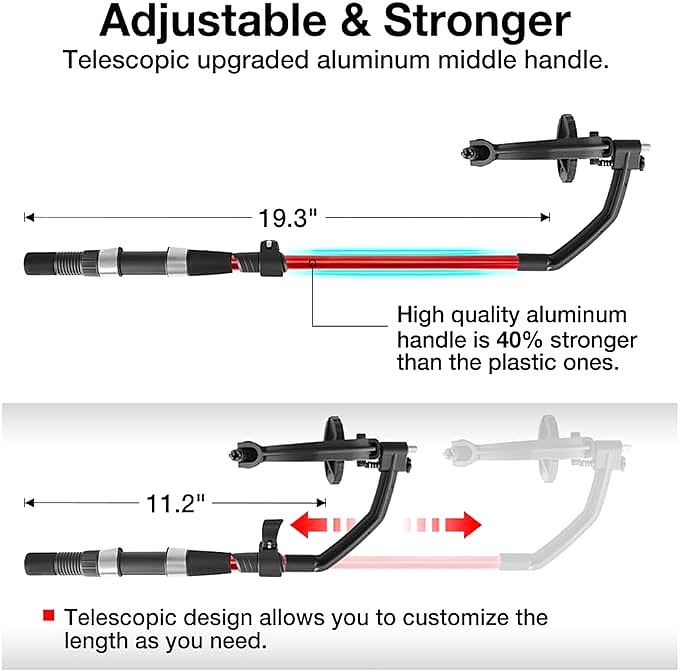

Furthermore, the upgraded aluminum alloy connecting rod provides a rigid spine for the operation. Plastic components under high torque can flex, causing misalignment and uneven spooling. By integrating aluminum bearings and a reinforced handle, the system eliminates this flex, ensuring that the alignment you set is the alignment you get, regardless of how much pressure you apply.

The Economic Argument: The Value of “Unspooling”

Perhaps the most overlooked aspect of line management is the economic one. High-end braided lines can be prohibitively expensive, yet often, only the first 50 yards see active duty. The rest remains pristine at the bottom of the spool.

Traditionally, removing old line to reverse it (putting the worn end at the bottom and the fresh end at the top) was a tedious nightmare involving empty soda bottles or messy piles of line on the floor. The unique unwinding function of the Speed X transforms this ordeal. By engaging the handle, you can mechanically strip line off your reel and back onto a spare bulk spool with the same speed and precision as loading it.

This capability effectively doubles the lifespan of your braided line inventory. Instead of discarding a spool because the top section is frayed, you simply reverse it. For the multi-species angler managing distinct setups—from heavy frogging gear to finesse drop-shot rigs—this ability to rapidly swap and save lines creates a versatile, modular arsenal without the recurring cost of constant replacement.

Adaptability in the Workshop

A tool is only as useful as its versatility. The modern angler’s garage is often a mix of spool sizes, from tiny 150-yard pony spools of fluorocarbon leader to massive 3000-yard service spools of backing. A rigid, one-size-fits-all approach rarely works.

The upgraded clamp mechanism on the Speed X addresses this by opening up to 4.13 inches (approx. 10.5 cm). This range covers the vast majority of consumer line spools. Combined with the adjustable middle handle, which modifies the leverage and positioning, the system adapts to the specific ergonomics of the user and the physical dimensions of the line spool. This adaptability ensures that whether you are preparing a micro-finesse reel for trout or a 400-size baitcaster for musky, the stability of the station remains compromised.

Conclusion: The Confidence of Preparation

Ultimately, investing in a dedicated line management system is an investment in confidence. It removes variables from the equation. When you are hooked into a trophy fish, running drag and testing your knots, the last thing you should worry about is whether your line was spooled with enough tension to prevent it from digging in.

Tools like the Piscifun Speed X represent a maturation in how we approach gear maintenance. They take a process that was once subjective and prone to error and render it objective, mechanical, and precise. By controlling tension, eliminating twist, and enabling efficient line rotation, you aren’t just winding string onto a spool; you are engineering a better day on the water.