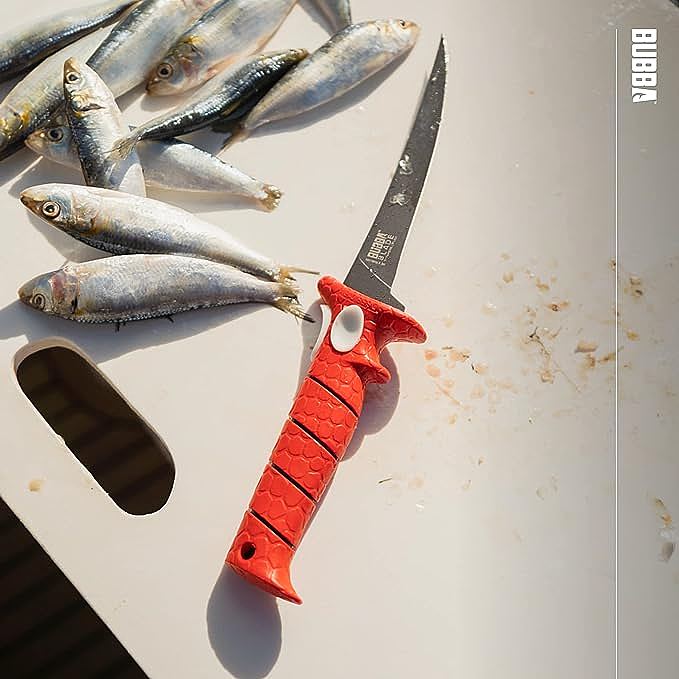

The Science of the Perfect Fillet: A Deep Dive into the Bubba BB1-7F Knife's Design

Update on July 31, 2025, 5:57 p.m.

The sun dips below the horizon, casting a golden glow across the water. The day’s thrill of the chase is over, but a different, more intimate challenge awaits on the cleaning table. For any serious angler, this is the moment of truth: transforming a beautiful catch into perfect, bone-free fillets ready for the pan. This task, a blend of art and anatomy, can quickly become a frustrating struggle with the wrong tool. A dull blade tears, a clumsy handle slips, and precious meat is lost. It’s here that a knife like the Bubba BB1-7F 7 Inch Tapered Flex Fillet Knife reveals its true character—not as a mere cutting implement, but as a masterpiece of applied science, engineered to make precision effortless. To truly appreciate it, we must look beyond its sharp edge and iconic red handle, and into the very molecules and mechanics that define its performance.

The Soul of the Steel

At the heart of any great knife lies its steel. The BB1-7F is forged from 8Cr13MoV, a name that, to a materials scientist, tells a compelling story. This isn’t just “stainless steel”; it’s a carefully balanced iron alloy. The “8Cr” signifies a high chromium content (around 13%), which is the key to its corrosion resistance. This chromium reacts with oxygen in the air to form a microscopic, passive layer of chromium oxide on the blade’s surface. This invisible shield is what stands guard against rust, regenerating itself if scratched—a crucial feature for a tool constantly exposed to moisture and salt.

The “0.8” (implied by the “8”) refers to the high carbon content. Carbon is the primary element that gives steel its hardness, allowing it to be heat-treated to a significant rating on the Rockwell Hardness Scale (HRC). This hardness is directly responsible for the blade’s ability to hold a razor-sharp edge through the demanding work of slicing through skin, scales, and flesh. The “Mo” (Molybdenum) and “V” (Vanadium) are vital supporting actors, helping to refine the steel’s grain structure during forging, which enhances toughness and wear resistance. In essence, the 8Cr13MoV alloy is a calculated compromise, engineered to deliver excellent edge retention without becoming so hard that it turns brittle and difficult to sharpen.

The Invisible Armor

Layered over this capable steel is a Titanium Nitride (Ti-Nitride) coating, the blade’s first line of defense. This is a concept borrowed from heavy industry, where Ti-Nitride is used to coat high-speed drill bits and cutting tools. Applied through a process called Physical Vapor Deposition (PVD), this technique bonds a thin, ceramic layer to the steel at a molecular level. The result is a surface that is significantly harder than the steel itself. This “invisible armor” provides an exceptional barrier against scratches from bones and scales, and adds another robust layer of corrosion protection. Furthermore, ceramic coatings have a very low coefficient of friction. This means the blade glides through fish with noticeably less effort, reducing drag and preventing meat from tearing or sticking—a subtle but significant advantage that elevates the filleting experience from a chore to a fluid motion.

The Physics of Finesse

Perhaps the most defining characteristic of the BB1-7F is its “Tapered Flex” blade. This isn’t just a marketing term; it’s a principle of mechanical engineering and blade geometry. The blade is designed to be thickest near the handle and progressively thinner as it tapers towards the tip. From a physics perspective, this design brilliantly manages stress distribution. When pressure is applied, a uniform blade has specific points where stress concentrates, making it prone to snapping. The tapered design, however, allows the entire blade to bend in a smooth, controlled arc. It can flex to follow the complex contours of a fish’s rib cage, maintaining constant contact to cleanly separate the meat, yet it retains enough backbone and rigidity near the handle for the initial powerful cuts through the skin. This engineered flexibility is the science behind the finesse, allowing the user to feel the bones and navigate around them with surgical precision.

The Science of a Secure Hand

A blade, no matter how advanced, is only as effective as the hand that wields it. The iconic BUBBA handle is a case study in ergonomics and the science of grip. The non-slip grip is crafted from a polymer, likely a thermoplastic elastomer, chosen for its high coefficient of friction. This material property ensures a secure purchase even when coated in water, slime, and blood, fundamentally enhancing safety and control. The handle’s shape is not arbitrary; it’s designed to fill the palm comfortably, reducing the muscle strain and fatigue that come with prolonged use. The integrated trigger grip and prominent safety guards are critical ergonomic features. They provide a fixed, intuitive point of contact for the fingers, allowing the user to apply precise force and direction without the hand slipping forward onto the blade. This synergy of material science and biomechanical design translates into confidence, allowing the angler to focus entirely on the delicate task at hand.

In the end, the Bubba BB1-7F is more than the sum of its parts. It is a harmonious system where the chemical resilience of the steel, the physical barrier of the coating, the mechanical elegance of the blade’s flex, and the ergonomic intelligence of the handle all converge. It stands as a powerful reminder that in the world of outdoor pursuits, the finest tools are born from a deep understanding of science. To know the principles behind the knife is to elevate one’s own craft, turning the simple act of filleting a fish into a final, satisfying celebration of the catch.